Learning from nature: Scientists create new material inspired by leaves to separate oil from water for cleaning up oil spills

05/08/2018 / By Janine Acero

Scientists have developed 3-D printed solutions to solve one of the most devastating man-made disasters. They looked at leaf structure to create a material that can separate oil and water, which has potential applications in safer and more efficient oil spill clean-up methods.

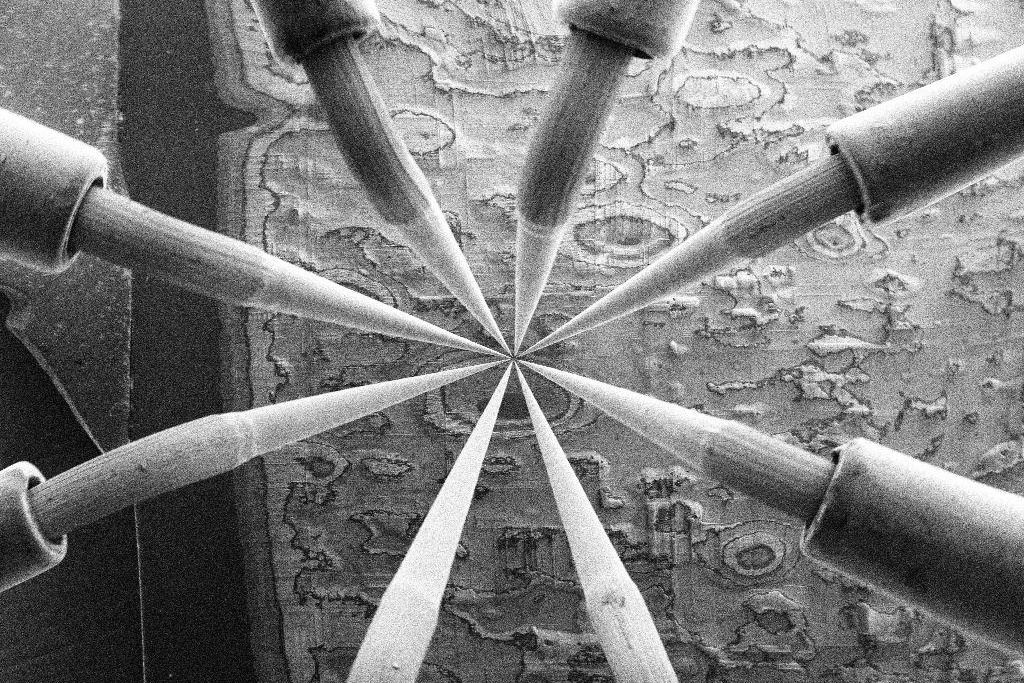

The researchers used 3D printing to mimic a biological phenomenon in leaves called “Salvinia effect,” which enables leaves to be ultra hydrophobic, or highly resistant to water, and retain a surrounding air pocket when submerged in water due to water-resistant hairs. Their study focused on an aquatic fern native to southeastern Brazil called Salvinia molesta.

The research team believes that the plant’s adaptation allowed this phenomenon. “I think the reason the plant’s surface is super-hydrophobic is because it lives on the water and requires air to survive,” Yang Yang, a postdoctoral researcher on Chen’s team, said.

The leaf hairs were found to be aligned in a structure that resembled a whisk or egg-beater, which the scientists explained is what gives the leaf surface its superhydrophobic property.

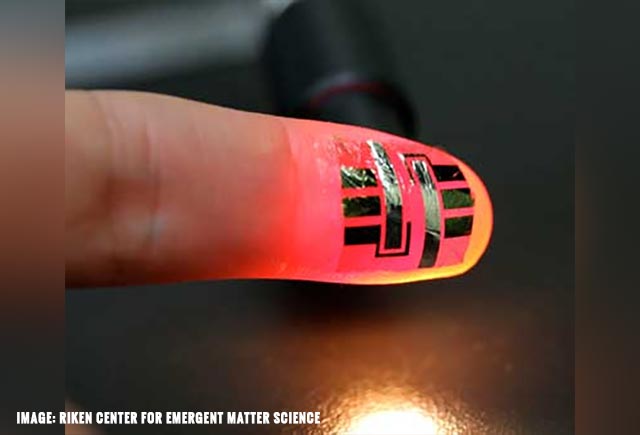

The scientists then successfully mimicked this egg-beater microstructure in samples made from plastic and carbon nanotubes, using a method called immersed surface accumulation 3-D printing (ISA-3D printing). The method allowed the team to demonstrate the fabrication of a material with both superhydrophobic and oleophilic (oil-absorbing) properties that, when combined, can be capable of highly efficient oil and water separation.

“We tried to create one functional surface texture that would be able to separate oil from water,” Chen said. “Basically, we modified the surface of the materials by using a 3-D printing approach that helped us achieve some interesting surface properties.”

The scientists have 3-D printed a prototype, and they hope the technology can be applied to manufacture materials in large scale to accommodate the growing demand for materials that can separate oil and water mixtures in vast bodies of water. Current methods require tremendous energy in the form of an electric field or mechanically-applied pressure.

In addition, the material is capable of transferring miniature volumes of liquid or “microdroplet manipulation,” which can be applied in a variety of applications such as droplet-based microreactors (devices used in chemical synthesis), nanoparticle synthesis, tissue engineering, drug discovery and drug delivery monitoring.

Droplet-based microfluidics is a tool used in various applications like cell cultures, chemical synthesis, and DNA sequencing.

One example of how high-performance microdroplet manipulation can be used for more efficient blood analyses is by dispensing microdroplets of blood to be combined with different chemicals for various tests.

“You can have a robotic arm with a gripper made to mimic ‘Salvinia effect,'” said Xiangjia Li, a Ph.D. student on Chen’s team and co-first author of the study. “No matter which way you move the arm, the gripping force is so large that a droplet will stay attached.”

Worst oil spills in the U.S.

On April 20, 2010, Deepwater Horizon, an offshore drilling rig, exploded and caused a massive oil spill in the Gulf of Mexico, which is considered the largest accidental marine oil spill in the world, and the largest environmental disaster in U.S. history. (Related: BP Deepwater Horizon oil spill found to have caused over $17 billion in environmental damage.)

Other devastating oil spill accidents in U.S. history include the Atlantic Empress/Aegean Captain collision in July 1979 and the Ixtoc I oil well that exploded in the Gulf of Mexico in June 1979 and continued until March 1980.

Head over to Inventions.news for more on nature-inspired innovations.

Sources include:

Tagged Under: clean water, environmental damage, future tech, inspiration from nature, man-made disasters, microdroplet manipulation, mimicking nature, nature inspired solutions, oil spill, oil spill clean-up, Salvinia effect, Salvinia molesta, superhydrophobic, ultrahydrophobic, water clean-up, water-repellent, water-resistant