Advancing detection and diagnosis: Scientists enable 3D printers to print glass using material called chalcogenide glass

10/31/2019 / By Edsel Cook

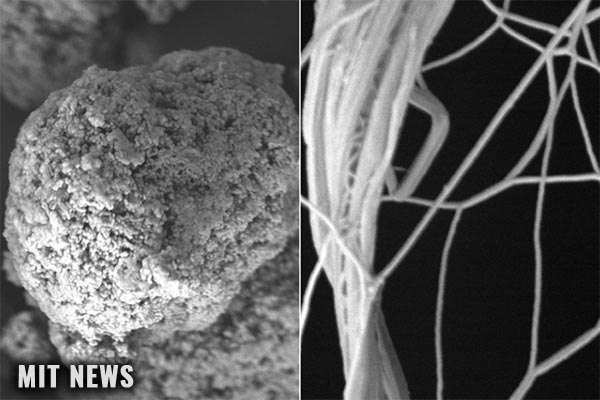

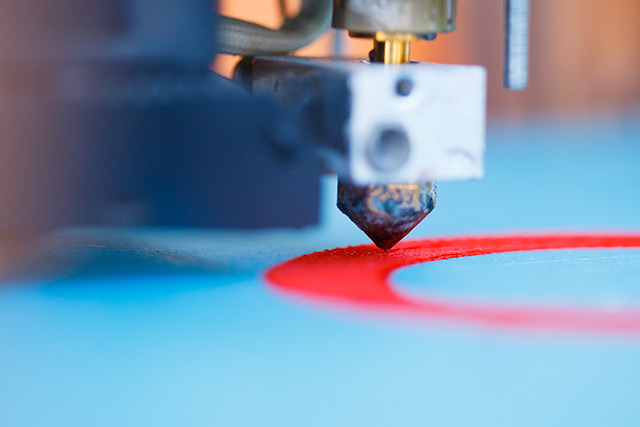

Additive manufacturing systems have added another challenging material to the list of things they may print on the fly. Canadian researchers demonstrated the capability to print out chalcogenide glass with a modified 3D printer.

Chalcogenide glass is a type of covalently bonded glass that contains certain chemicals called “chalcogens.” It sees extensive use in optical parts that cover the mid-infrared wavelengths of light.

Thanks to the efforts of researchers at the Universite Laval (UL), 3D printers may produce the difficult-to-manufacture glass. With further improvements, they may one day make complicated glass parts and optical fibers.

The ability to 3D-print chalcogenide glass will help drive down the cost of producing biomedical devices, sensors, and telecommunication parts. It also makes it possible to manufacture new types of those gadgets.

The UL’s Centre d’Optique, Photonique et Laser (COPL) institute conducted the study. Led by author Patrick Larochelle, the researchers took a commercial 3D printer and altered it to extrude glass instead of the usual plastic polymers.

Larochelle’s team borrowed ideas from fused deposition modeling. In that approach, the 3D printer melts a plastic filament, then extrudes layer upon layer of the material to create a highly detailed product.

Chalcogenide glass melts at lower temperatures – perfect for 3D printers

“3D printing of optical materials will pave the way for a new era of designing and combining materials to produce the photonic components and fibers of the future,” explained UL researcher Yannick Ledemi, who assisted Larochelle and the others. “This new method could potentially result in a breakthrough for efficient manufacturing of infrared optical components at a low cost.”

Most types of glass require exposure to high temperatures before they begin to soften. Outright melting the material takes even more heat and energy.

However, chalcogenide glass happens to grow softer at a lower temperature than other counterparts. The UL-COPL researchers took advantage of this unique property to make it possible to extrude the glass.

Their baseline commercial 3D printer achieved a maximum extruding temperature of 500 F (260 C). They modified the device so that it reached 626 F (330 C) during the extrusion process, hot enough to melt chalcogenide glass.

Their next step was creating chalcogenide glass filaments with dimensions that matched those of the commercial plastic ones fed into their modified 3D printer.

Last but not least, they wrote programs for the printer to create two samples out of chalcogenide glass. The device succeeded in printing out the complex shapes. (Related: New “living” tattoos are made with a 3D printer, respond to changes in the environment.)

Future 3D printers may eventually use glass as raw materials for products

Ledemi explained that his team’s technique took full advantage of the softer property of chalcogenide glass. They are currently investigating the possibility of using other methods to print harder types of glass.

A printer with the ability to create products made from harder glass may open the door to 3D printing of parts that use more than one material. Such additive manufacturing devices will feature new extrudes, and they will use glass and specialized polymers to make items that perform multiple roles.

Glass-compatible 3D printers may also produce fiber preforms with complicated shapes, more than one ingredient, or both. The printers may churn out large volumes of the preforms or infrared glass parts at a lower cost than current industrial processes.

“3D printed chalcogenide-based components would be useful for infrared thermal imaging for defense and security applications,” Ledemi proposed. “They would also enable sensors for pollutant monitoring, biomedicine and other applications where the infrared chemical signature of molecules is used for detection and diagnosis.”

Visit Breakthrough.news for more studies on breakthrough 3D manufacturing technology.

Sources include:

Tagged Under: 3D printers, 3D printing, additive manufacturing systems, breakthrough, glass, goodtech, innovation, inventions, manufacturing, materials research, materials science, medical technology, optical materials, raw materials, science and technology

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 FUTURE SCIENCE NEWS